Questions about the advantages of plastic caps with innovative biodegradable P-Life/Go Green technology? Contact us and request more information! Purchase new covers produced with sustainable technology!

Friend of Nature

We are Bral-Max

Sustainability

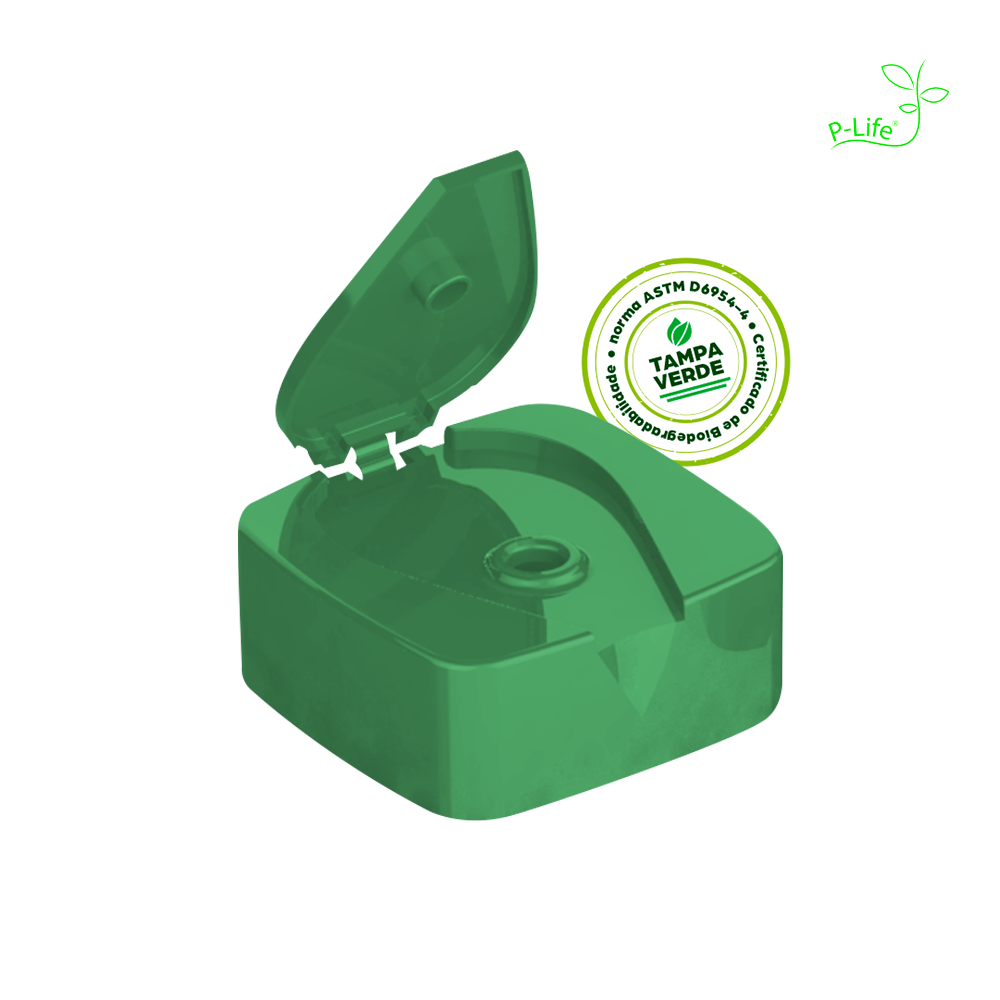

Bral-Max Green Cover Line

We have a line of plastics with biodegradable technology P-Life / Go Green.

Produced with P-Life technology, oxy-biodegradable Plastic is a sustainable plastic alternative, with 100% renewable resin, coming from sugarcane, resulting in ecologically correct plastic parts, in line with the “zero carbon” concept, preserving all the properties and quality required of plastic, in addition to keeping it suitable for recycling.

< p>O oxy-biodegradable plastic, despite being obtained from Polyethylene or Polypropylene, derived from petroleum or Ethanol, contains an additive that accelerates its degradation.

Approved in tests carried out – in accordance with BS 8472 standards , ASTM 6954-04, among others – o oxy-biodegradable plastic also adds the use of it in a recyclable process, like conventional plastics, in their pre-degradation phase.

This technology is available in several models and cap colors. Consult us!

ABOUT GO GREEN:

In synthesis, it can be said that Go Green is a resin obtained by a pro-degrading process, based on fatty acid (derived from oil from coconut palm), sodic clays and lubricants, capable of converting naphtha derivatives (polyethylene, polypropylene, PET, polystyrene and other polymers) into biodegradable products.